Sortation systems automatically separate and sort products into different routes and conveyor lines. They can also dispense directly into bins, bags or stillages. Lines run with product moving continuously through the system and therefore high levels of throughput can be achieved.

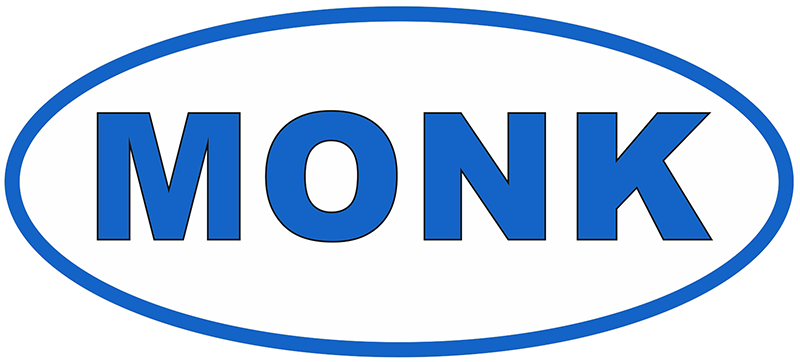

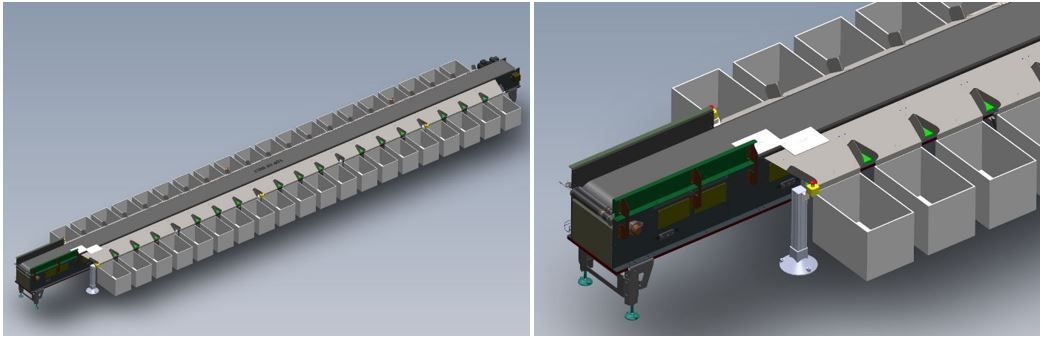

Monk Conveyors used the Intralox ARB™ S7000 Sorter in one of our latest installations. The S7000 bi-directionally sorts a wide range of products at high throughput rates of up to 500 per minute. In this project, it was used for sorting greetings cards, bags and gifts into 40 bin locations. The Sorter can divert an item efficiently to the left or to the right of the main central conveyor with smooth and safe operation.

Each product has a barcode which is scanned at the start of the line. The product is then diverted off the central belt into the correct bin location. There is a continuous flow of products with many on the belt at one time. From an initial concept drawing the 3D CAD model brought the system to life ready for the build, installation and software.

Software takes the information from the barcode reader and controls the operation of the S7000 Sorter. Our system communicates via TCP/IP to the customers Warehouse Management System (WMS). We receive barcode data from our scan and request job information from the WMS. The job information is then used to route the product to the correct bin location.

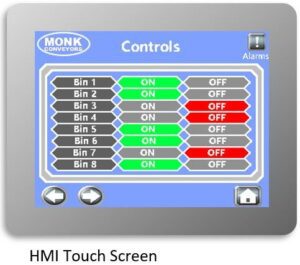

An operator touch screen allows bin locations to be easily turned on and off. Active bins will be highlighted green and inactive bins highlighted red.

Any products which have already been scanned continue to the bin location which is switched off, but any new products continue to an end of line location so they can be manually checked and sorted.

A high specification Keyence SR-5000 barcode camera reader was used to reliably read a wide range of product barcodes. This reader features an Ultra-wide field of view, reading depth and high-speed capabilities.

The camera-based system means products do not need to be orientated for them to be read and this cuts down on equipment costs.

Please contact us to discuss warehouse and sortation applications.