Spiral Conveyors

Spiral Conveyor – Single Lane

MONK Conveyors build spiral conveyor systems using Apollo VTS’s world’s leading vertical conveying systems. Apollo VTS based in The Netherlands manufacture leading high-quality machines.

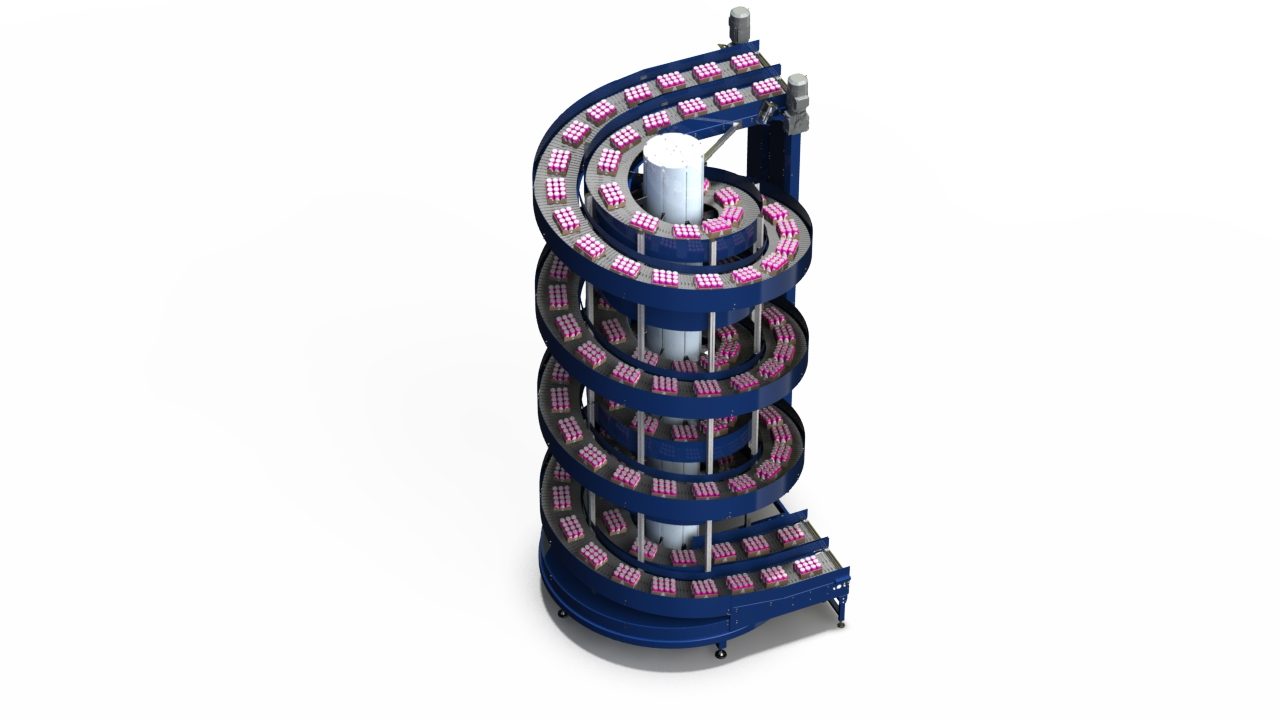

The Apollo Single Lane Spiral Conveyor transports products up or down in a continuous flow and has proven to be a very reliable spiral conveyor system that increases efficiency while conserving valuable floor space.

Single Lane Spiral Conveyor features:

- Loads up to 50kg/meter.

- Speed 60 m/minute.

- One motor.

- Designed to operate 24/7.

- Small footprint.

- Low friction operation.

- Built-in protection.

- Low noise level.

- No lubrication under the slats required.

- Low maintenance.

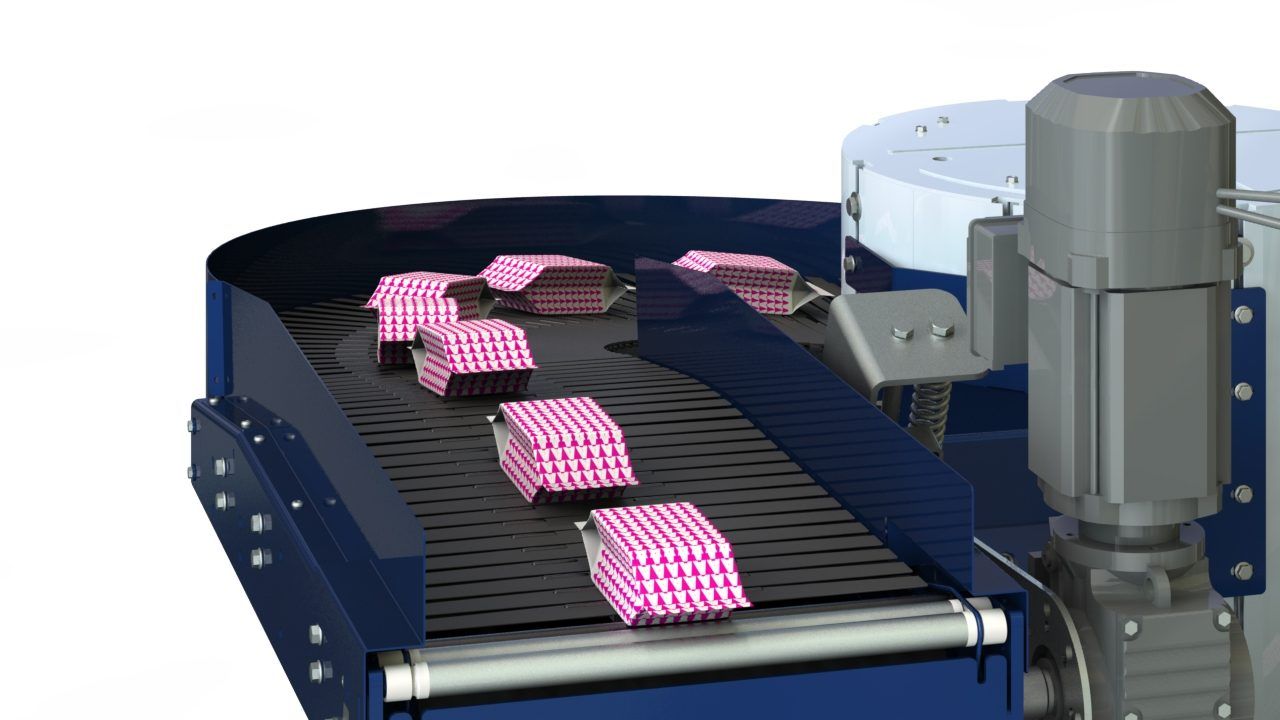

The Spiral Conveyor consists of a moving belt which revolves around a central column. It can be used to move a wide range of products between floor levels or over walkways. The spiral belt guide system runs on precision bearings so there is only rolling friction and therefore the noise level is very low.

Multiple products are suitable for a spiral conveyors such as; bags, bundles, totes, trays, cans, bottles, containers, cartons and wrapped and unwrapped items. Spiral systems work for many types of industries: food industry, beverage industry, newspaper industry, pet food & personal care industry and others.

Dual Lane Spiral Conveyors and Mass Flow Spirals are also available. Please contact us for further information at Monk Conveyors.

Vertical Spiral Conveyor – Dual Lane

The Dual Lane Spiral Conveyor from Apollo transports materials and products up or down in a continuous flow. Similar to the Single Lane Spiral Conveyor, but the Dual Lane Spiral Conveyor transports double the capacity, which results in twice as much throughput. This makes our Dual Lane Vertical Conveying System an efficient and reliable option for businesses with higher capacity needs, but a limited amount of floor space for handling systems.

- Dual Lane Spiral Conveyor features.

- Loads up to 50 kg/meter.

- Speed 60 m/minute.

- Two separately driven tracks.

- Operate 24/7.

- Small footprint.

- Low friction operation.

- Built-in protection.

- Double capacity.

- Low noise level.

- No lubrication under the slats needed.

- Low maintenance.

This Vertical Spiral consists of two separately driven conveyor belts that revolve around a centre. It can be used to move a wide range of products between floor levels or over walkways. The spiral belt guide system runs on precision bearings so there is only rolling friction and noise level is very low.

There are multiple products which are suitable such as; bags, bundles, totes, trays, cans, bottles, containers, cartons and wrapped and unwrapped items. Spiral Conveyor systems work for many types of industries: food industry, beverage industry, newspaper industry, pet food & personal care industry and others.

The Apollo Dual Lane Spiral Conveyor has two tracks that are separately driven. The two tracks can be synchronized with the same speed, run at different speeds, or run in the opposite directions with the same or different speed.

The two tracks of the Dual Lane Spiral Conveyor can be delivered in different widths, and it is also possible to have the two lanes with different infeed and outfeed heights.

Single Lane Spiral Conveyors and Mass Flow Spirals are also available. Please contact us for further information at Monk Conveyors.