Packing Lines

Packing conveyor systems which are designed around packing tables and benches help to reduce manual handling and improve efficiency. Packing Lines convey either packing material or products to and from the packing staff. This allows them to focus on packing and not have to move material or products around.

Our packing lines can incorporate devices which control the flow of work and make sure that every person is continually fed with work. The system can be designed so staff pack directly on the conveyor, take packing material from the conveyor, or put completed packed work on a take away conveyor. Packing stations must also be ergonomic and comfortable for staff to use. Optional display screens can be provided to show targets and achievements. Our barcode system can also be used to retrieve information to route work or add Sortation.

Zero Line Pressure conveyor techniques can be used to keep work apart by moving it in small powered zones. There is no back pressure on the packing line and an operator can easily remove any product from the conveyor. The queue of work then automatically moves forwards to keep the packing conveyor full.

Safety rope pull lines are fitted in case of an emergency and local stop/start or pause buttons can give operators full control. Every packing conveyor system can be slightly different so please contact our sales team and we will be very happy to discuss your application. Examples of two types of packing line are shown below.

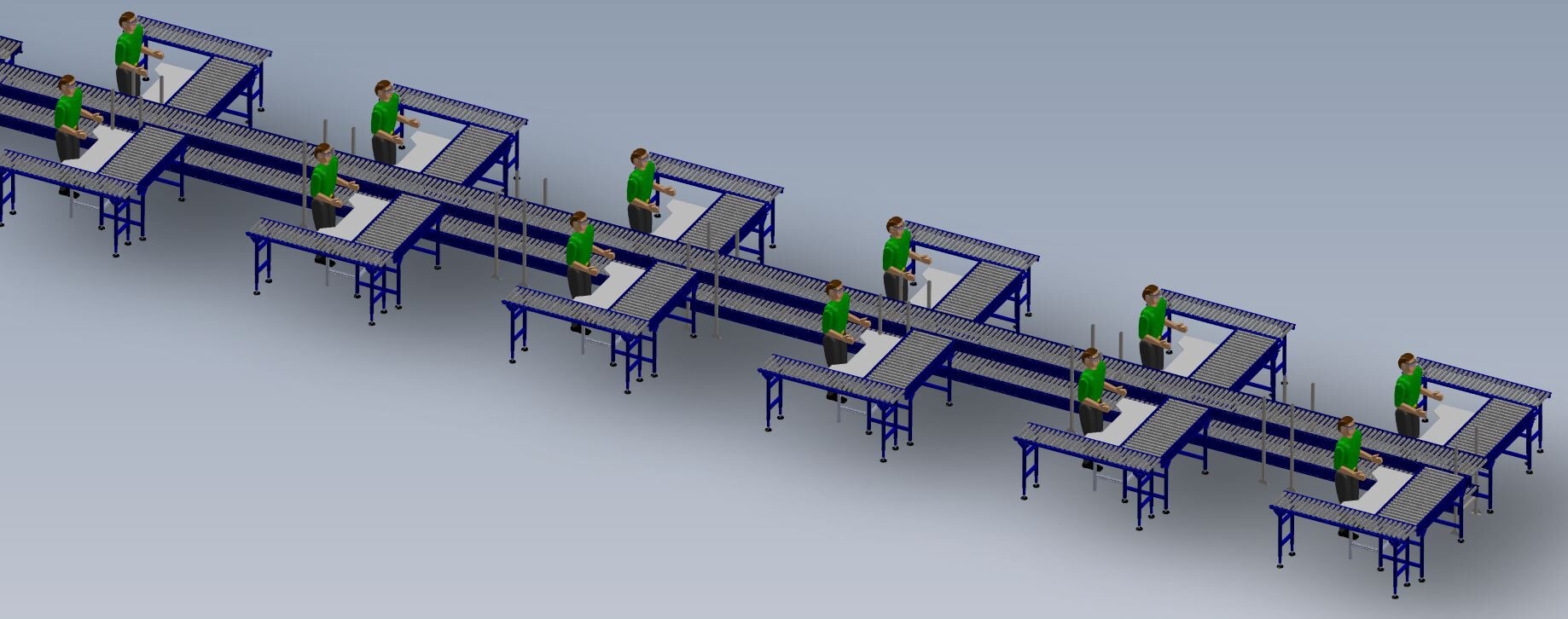

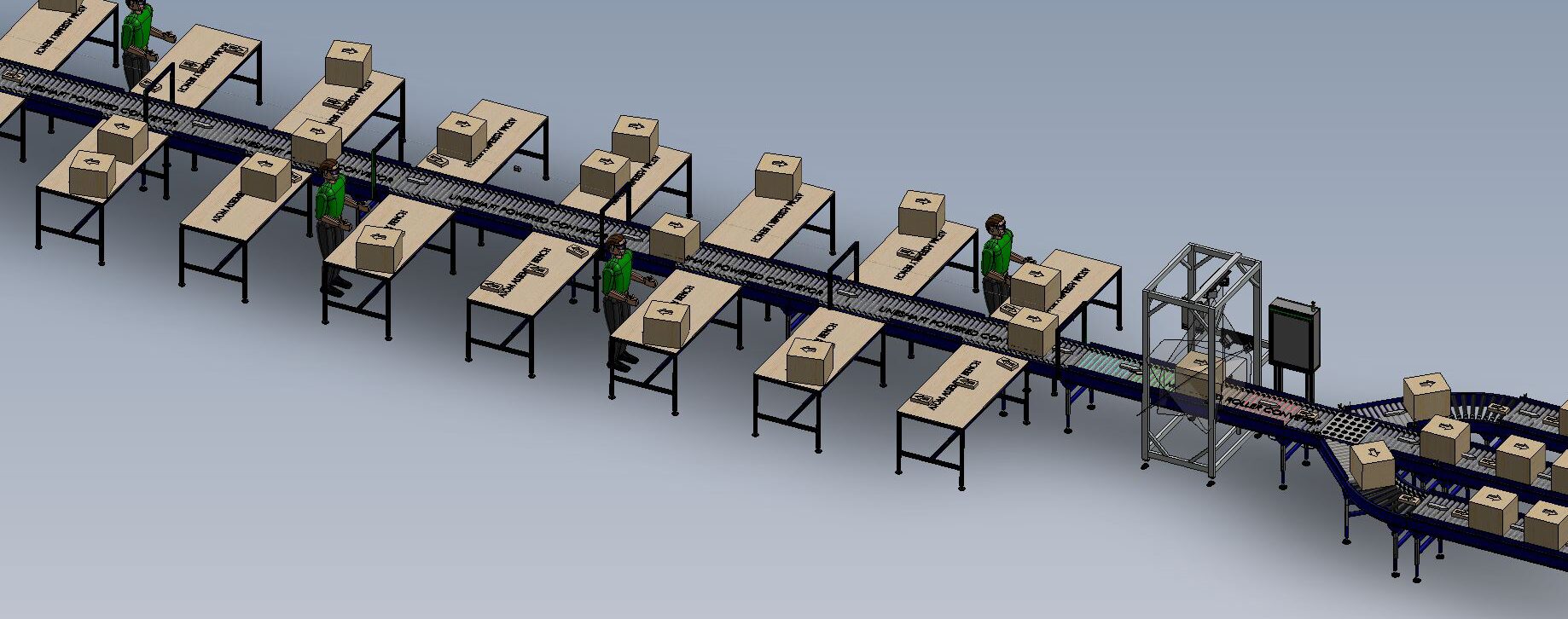

What is a Packing Station Line

Two Tier Packing Line

Two central packing conveyors are used. One conveyor brings work to the packing staff and the other is used to take packed work away. They can be mounted one above the other so additional floor space is not required.

Take Away Conveyor – Packing Staff place completed work on the central conveyor and it takes work away to the dispatch area or next part of the warehouse.

Supply Conveyor – Product is fed to all the packing staff. The line is kept full so all staff have products ready to take at all times. Gaps are created by our system so it is easy to remove product from the conveyor.

Optional Packing Bench Conveyors – The example below shows the addition of conveyors around each packing bench. This means that products can queue around each bench so there is always a good selection of work for each operator.

Single Tier Packing Line

A single central conveyor can be used to either Supply work to packing tables or Take Away work.

Take Away Method – Packing Staff place completed work on the central conveyor and it takes work away to the dispatch area or next part of the warehouse.

Supply Method – Product is fed to all the packing staff. The packing line is kept full so all staff have products ready to take at all times. Gaps are created by our system so it is easy to remove products from the conveyor.

Optional Packing Bench Conveyors – The addition of conveyors around each packing bench means that product can queue at each bench. Then there will always be a good selection of work ready for each operator. This is shown in the Two-Tier Packing Line diagram.

Online Cosmetics Packing Conveyor System

Packed Product Taken to Dispatch

Vegetable Packing Line with Empty and Full Basket Feeds