Sortation System

A sortation system automatically separates and sorts products into different routes and conveyor packing lines. A sortation conveyor system can also dispense directly into bins, bags or stillages. Lines run with product moving continuously through the system and therefore high levels of throughput can be achieved.

Sortation Conveyor

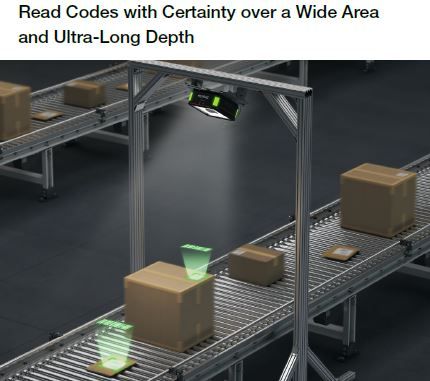

A sortation conveyor system can sort products and parcels by barcode data, RFID data, colour, size or image recognition using a camera system. It can be handled using a range of standard options including diverter arms, side belts, air blows, switch roller sorters and plastic belt with integral rollers.

Fast-moving industries such as Retail / E-Fulfilment, Warehouse and Distribution centres can see major improvements in efficiency and capability. A small footprint often means the ability to increase capacity without the need to increase floor space. We work closely with our customers to understand their process and design a sortation system which works within their current and future needs.

Sortation System for Flow Wrapped Packs using Air Nozzle

Three Way Parcel Sortation with Barcode Scanning

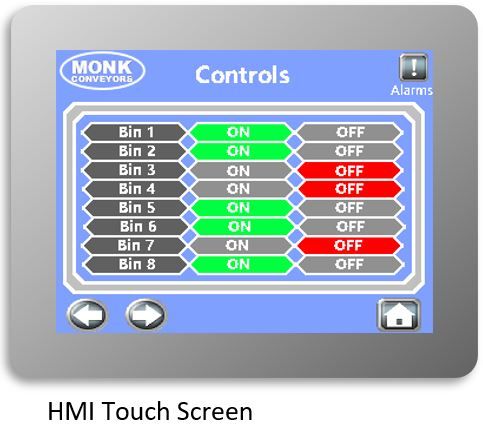

A large range of product shapes and sizes can be sorted and handled with a sortation system. From parcels, boxes, cases, and cartons, to shrink-wrapped packages, books, mail, totes, polybags and letter-sized items. Sortation conveyors are designed to eliminate product damage, being gentle, maintaining a continuous flow, reducing accumulation, and achieving product gapping. Touch Screen displays are supplied which make it easier for operators to run a system. Clear information is displayed along with help screens. Fault finding messages make it easier to find problems quickly.

What is a Conveyor Sortation System?

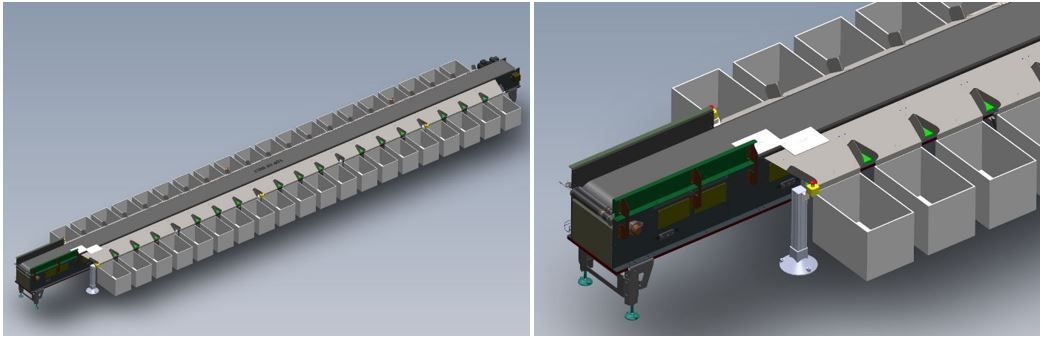

Case Study - Sortation System

The Head of Online Fulfilment for Card Factory and Getting Personal explains how efficient Sortation Systems and Packing Lines have helped them with the growth of the company.

Plastic Sortation Conveyor Belt with Integral Roller

Monk Conveyors uses the Intralox ARB™ S7000 Sorter. The S7000 bi-directionally sorts a wide range of products at high throughput rates of up to 500 per minute. The sortation project shown below shows greetings cards, bags, and gifts sorted into 40 bin locations. The sortation conveyor can divert an item efficiently to the left or to the right of the main central conveyor with smooth and safe operation.

Each product has a barcode which is scanned at the start of the line. The product is then diverted off the central belt and sorted into the correct bin location. There is a continuous flow of products with many on the sortation conveyor belt at one time. From an initial concept drawing the 3D CAD model brought the system to life ready for the build, installation, and software.

The Sortation System Software takes the information from the barcode reader and controls the operation of the S7000 Sorter. Our system communicates via TCP/IP to the customers Warehouse Management System (WMS). We receive barcode data from our scan and request job information from the WMS. The job information is then used to sort and route the product to the correct bin location.

An operator touch screen allows bin locations to be easily turned on and off. Active bins will be highlighted green and inactive bins highlighted red.

Any products which have already been scanned continue to the bin location which is switched off, but any new products continue to an end of line location so they can be manually checked and sorted.

Mimic screens can show a graphical representation of the sortation conveyor line. They can then display the status of each part of the line by changing colour. If there is a blockage, a section of the line can be highlighted to show an operator the location of the problem. Screens can also allow operators to adjust the line settings and these can be password protected to ensure only trained personnel have access.

A high specification Keyence SR-5000 barcode camera reader can be used to reliably read a wide range of product barcodes. This reader features an Ultra-wide field of view, reading depth, and high-speed capabilities. The camera based sortation system means products do not need to be orientated for them to be read and this cuts down on equipment costs.

Remote access to the PLC and barcode systems means that we can dial in to make minor software changes and assist site with problem-solving. All sortation systems are mechanically and electrically installed with full handover and training. Service and maintenance contracts can be provided along with critical spares.

Please contact us to discuss your project and we will help to design and specify the most appropriate conveyor sortation system for your needs.