Pallet Conveyor System

A pallet conveyor system is ideal for a product which needs to be held individually and moved along a conveyor on a pallet or puck. The product can be held accurately in a jig or fixture which is secured to the pallet. A pallet conveyor system is very good for products which are a difficult shape to feed, have a surface finish which needs protecting and where products need to be stopped in an accurate position to be worked on by an operator or machinery.

Our pallet stations lift the pallet from the belt and clamp it accurately in position. This means assembly or testing can be carried out on the product while the conveyor is free to move underneath.

The design of our system is modular which makes it easy to install and easy to reconfigure in the future. Products from medical to the automotive industries can benefit from the system to efficiently and automatically move work to each assembly and test station.

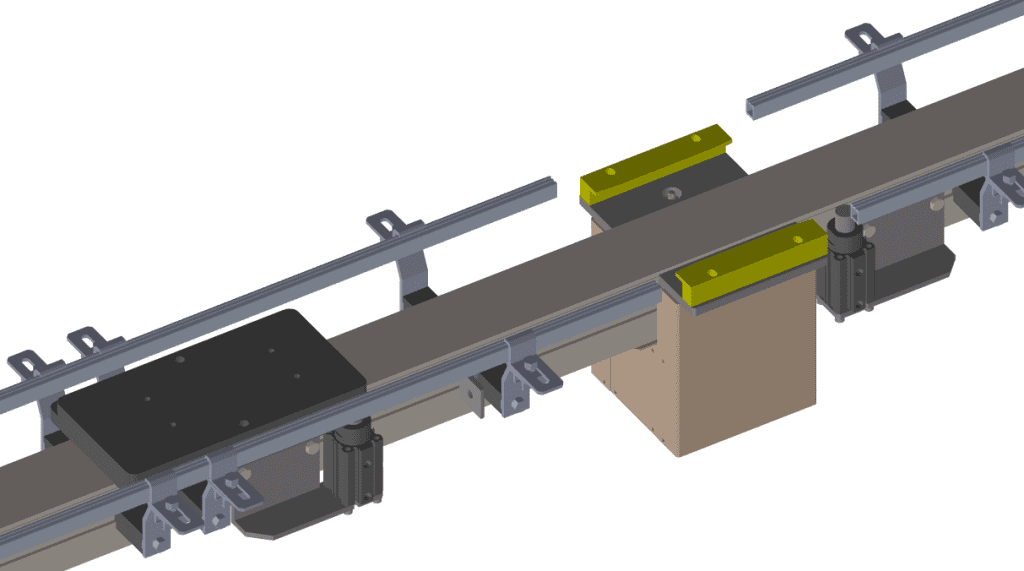

Pallet Station – Pneumatically Operated Lift

MONK Pallet Stations have a highly accurate lift and clamp mechanism and can take a heavy vertical load of up to 50kg. The pallet stations are a standard modular design which can be moved along the conveyor. They incorporate a location gate (stopper cylinder), sensors and an RFID reader to identify the pallet. Pallets are accurately located and lift away from the MM moving belt so there is no loading.

- Robust powder coated mild steel welded body with precision machined slide bores

- Drylin Igus Bushes

- Precision hardened and ground locator pins

- Vertical loading up to 50kg (when lifted from the belt)

- Pallet clamping accuracy of +/- 0.2mm

- Stainless steel satin finish outer covers

- Festo or SMC Pneumatic cylinders

- Reed Switches

- RFID Read Head with standard 5m lead

- Mounting holes for support leg

- Low maintenance design

- 1-Year mechanical warranty

Pallet Location Gates

Pallet gates use a stopper cylinder to stop the pallet in position. The cylinders are robust with a guided nose to take high side loads. Damped stop versions are also available. They can be positioned along the conveyor.

- Mild Steel Bracket

- Stopper cylinder guided nose, 32mm bore and 20mm stroke

- Reed Switch

- In position Sensor

Pallet Diverter

Diverts the pallets onto another conveyor. This allows pallets to be routed to a different location or assembly line.

- Rotary Actuator with Arm

- Sensors to detect pallet position

- Reed Switches

Pallets

Pallets are accurately machine from an engineering plastic Delrin which offers high stiffness, low friction & wear, chemical resistance and good dimensional stability. The product fixture can be securely fixed to the pallet.

- Machined pallet manufactured from Delrin 2700 NC010

- Side sensor bar mild steel zinc plated

- End stop bar mild steel zinc plated

- RFID tag

- Hardened steel headed drill location bushes

- Fixing Holes for component fixture or jig

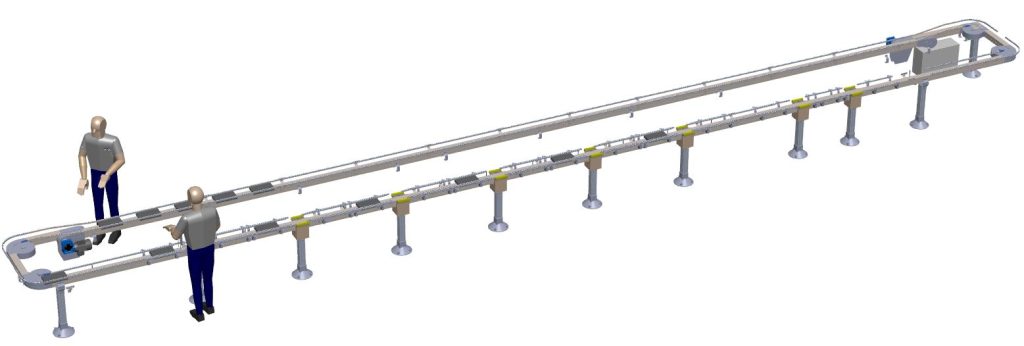

Conveyor System MM

The conveyor moves the pallets smoothly between the machines or work stations. Modu System conveyors are based on a close-fitting flexible chain. Compact horizontal bends allow our systems to use minimum floor space. The system is easy to maintain or even modify in the future.

- Robust anodised aluminium Beams

- Low friction slide rails

- MODU System quality Acetal Flexible Chain

- Tight radius Wheel Bends

- New sections are easily added for future modifications

- Low maintenance design