Conveyor Control Systems

A key part of any automation machinery or system is the electrical conveyor control system and software. This controls how the system operates and provides control and information to staff and maintenance.

We design and build automation and conveyor control systems and carry out full mechanical, electrical, pneumatic and software installation and setup. Conveyor controls range from a single motor, up to a full control system with a HMI touch screen, line mimic and bar code system.

Our electrical control panels are designed and built in house. We also have our own software engineering team for both PLC and PC based software. This helps us provide a high level of flexibility and maximum support to our customer.

The conveyor control system will utilise an industrial Siemens or Allen Bradley PLC. This will operate all conveyor motors, sensor and pneumatics. It will also control the operator interface HMI touch screens. Our PC based systems use an industrial server or panel mounted PC.

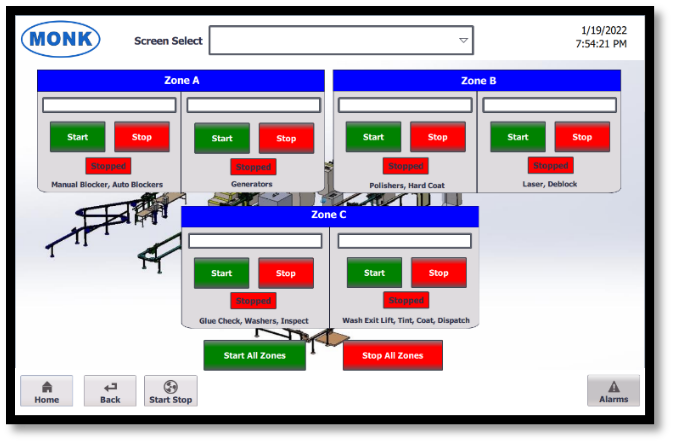

Operator Conveyor Control Touch Screens

HMI Touch screens are designed to be intuitive and easy for operators to use as a conveyor control. Screens make it easier for operators to run a conveyor system. Clear information is displayed and operator help screens are included. Fault finding messages can make it easier to find problems quickly.

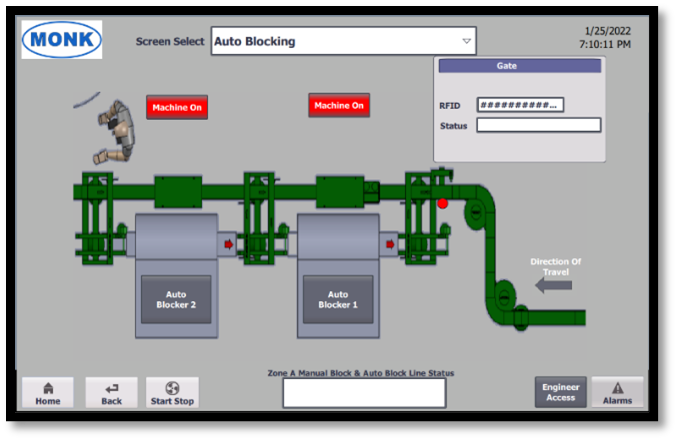

Mimic screens show a graphical representation of the production line. They can display the status of each part of the line, by changing colour to indicate if there is a problem or showing which status the line is in. If there was a blockage, a section of the line may show in red so an operator can go straight to the problem area.

Screens can also allow operators to adjust the line settings and these can be password protected to ensure only trained people have access.

Production performance can be displayed. Information on how many jobs are in the system, or a count of how many jobs have been sent to certain machines can be recorded. See more information in the KPI and Screen Reporting section.

Operator Interface Screens with Video

The screens allows the use of complex animations, video display, and a versatile user interface, which allows the POS-HMI display to show operators instructions, animations and videos. This is especially important for companies that manufacture many different products on the same production line, and the instructions on the display ensure the operator is able to keep track of what operation to apply to each product type.

Monk use a custom HMI solution, due to the complex graphical, processing and interfacing requirements. This would not have been possible to implement to the same level of quality using off-the-shelf HMIs.

The built-in magstripe card reader on the display is used by Monk’s software for user authentication and to identify the user.

Cutting edge conveyor control touchscreen for operator interface:

Ultra-flat touchscreen

Pole mountable

Energy efficient

Windows operating system

Solid state hard drives

Contemporary looking

Media screen

Remote Access

Our Remote Access System to the PLC/PC and also the Barcode/RFID system means that we can “dial-in” to make minor software changes and assist site with problem solving. This allows for improvements or changes to be made quickly and without a software engineer visiting site.