Conveyor System Videos

View our YouTube page for more videos.

View our YouTube page for more videos.

Customer Interview at Card Factory

The Head of Online Fulfilment for Card Factory and Getting Personal explains how efficient Sortation Systems and Packing Lines have helped them with the growth of the company.

Customer Interview at Norville

The managing director of Norville explains how our team designed and installed a tailored conveyor feed system which helps improve their productivity.

Overview of MONK Conveyors

Meet some of our team and learn about our company and what we can offer. See how we can work with you to provide the best possible solution and how we will work hard to support you as a customer.

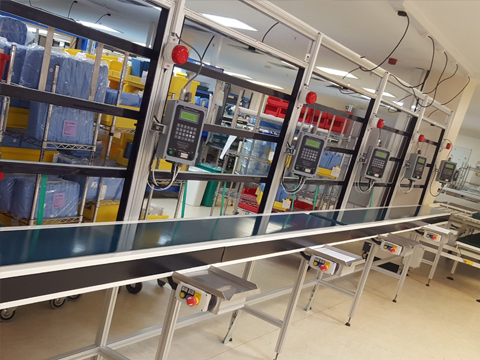

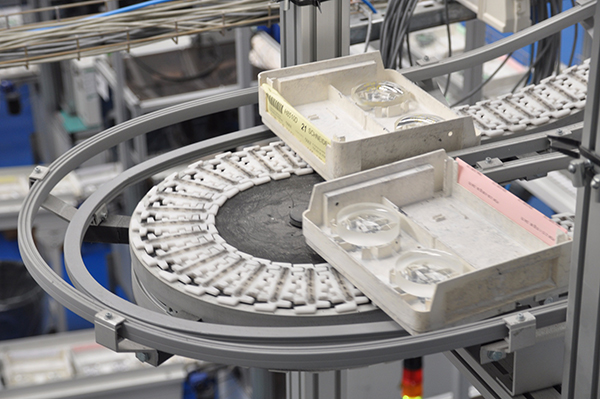

Conveyor Project Examples

We can supply small individual conveyors, through to complete fully automated factory installations. Our systems use PLC control with distribution software, sensors, pneumatics and electrics. Our installation and service team will give you full support and training.