Imagine if you invested in automation equipment which saved space, time and reduced your costs. A conveyor can reduce handling costs inside your site. A more complex conveyor system can automatically route products or packing materials to operators and machines. Monk Conveyors specialises in conveyor systems designed to automate your business.

Have you considered how every hour of lost productivity will add up into days and months of lost operational costs. While labour costs are increasing, companies need to automate to stay competitive and ahead of the competition. Improve your productivity now, to see days, months and even years of cost saving benefits.

Introducing automation can be simpler and take less time than you think … with MONK

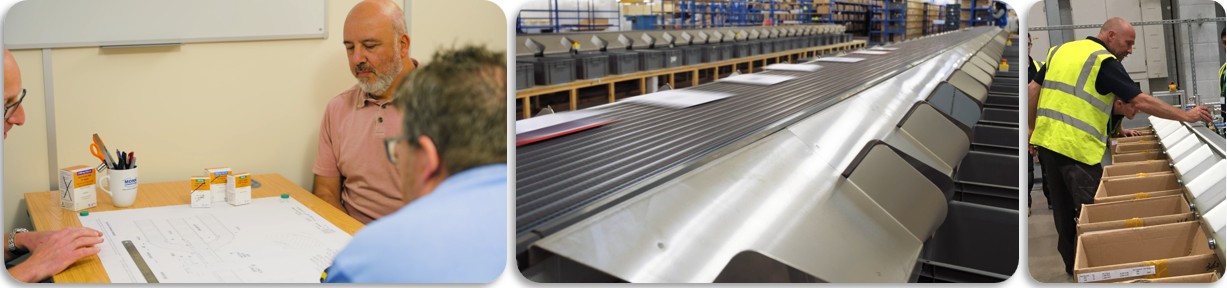

At Monk we make introducing automation as simple and easy as possible. We do this by looking after the whole process from start to finish.

Step 1 – We can help you identify an area which can be improved, or you can tell us an area which you need to improve.

Step 2 – We will show you economical solutions using standard equipment where possible within your budget.

Step 3 – We will give you a proposal which will include everything, right from the concept through to the installation, switch on, handover and training your staff – a Full Turn-Key Solution.

Our service then continues with aftersales support, service visits, spares, and this provides peace of mind. Our systems are modular and can be expanded or modified in the future as your business changes. Contact us today to start your discussion on automation.

How can we help? Email us Today

Call us on +44 (0)1252 369800

Automation Example 1 – Packing and Dispatch Conveyor Lines

Packing Conveyor Lines are designed around packing tables and benches to help to reduce manual handling and improve efficiency. Packing Lines move packing material and products to and from the packing staff. This allows staff to focus on packing and not spend time moving material or products around.

Watch Our 60 Second Explainer Video

Our packing lines can control the flow of products and make sure that every person is continually fed with work. The system is easy to use and improves efficiency. Packing stations are also designed to be ergonomic and comfortable for staff to use.

We also supply Belt Conveyors, Roller, Pallet, Carton Lifts, Spiral Conveyors, Flexible Chain, Matt Top all with full Electrical Control, Software and Installation

Monk Conveyors supply and install full working systems which are designed to suit your specific needs. We install full pneumatic and electrical control with operator touch screens.

Our control systems range from simple stop starts up to barcode capable controls, capable of communicating with your Warehouse Management System (WMS).

Our team have built up over 25 years experience in conveying and handling equipment. Call us today and we look forwards to discussing your application.

Tel: +44 (0)1252 369800