Filling Postal Bags and Cartons

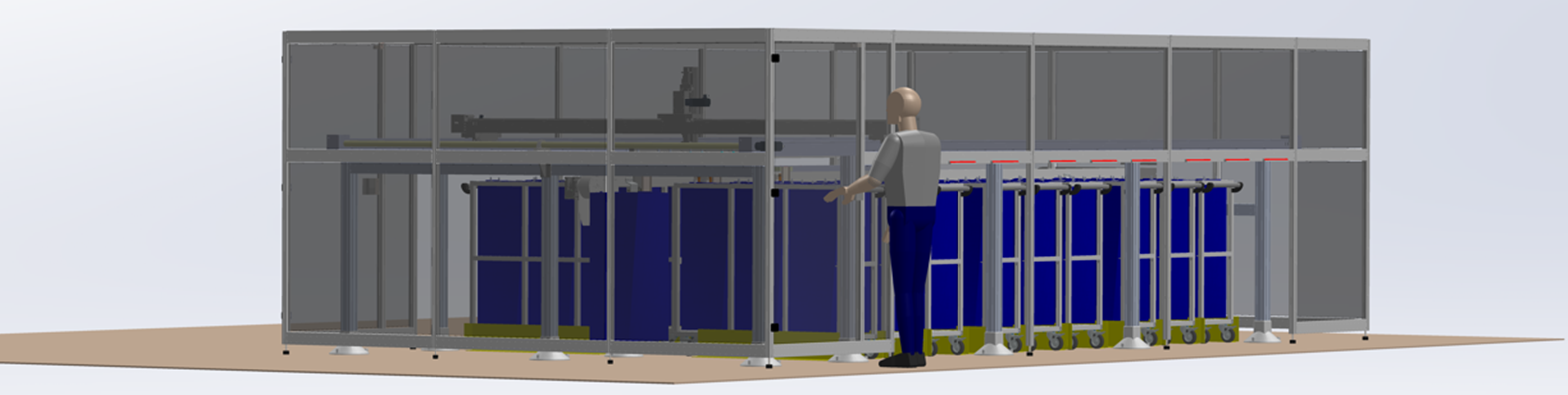

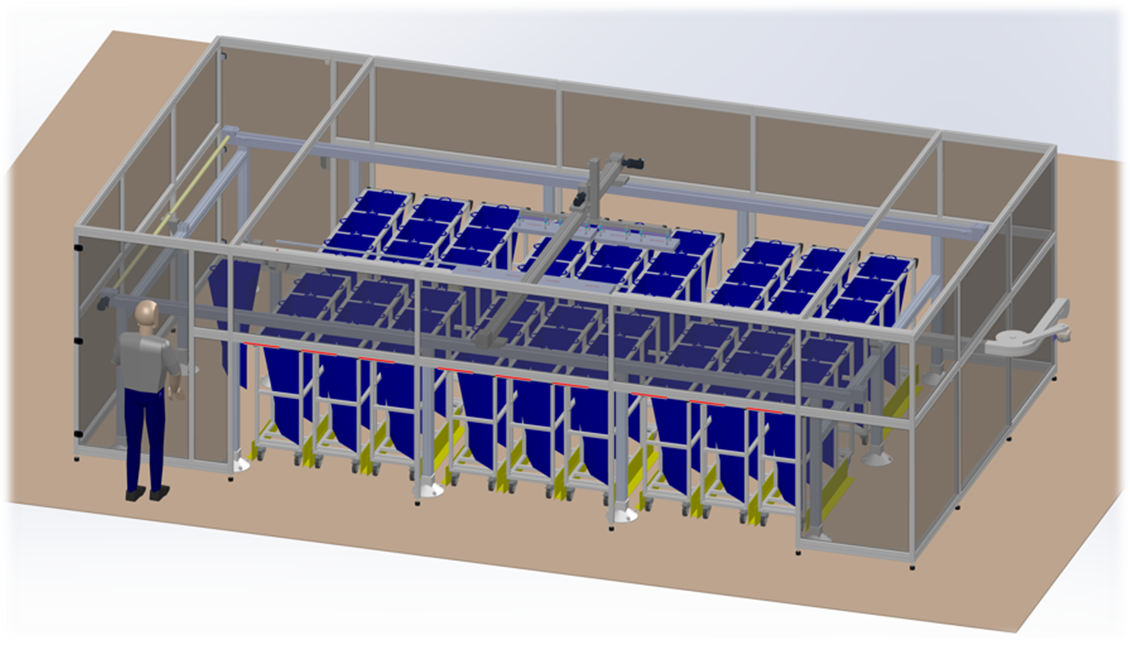

MONK XY-A System – For Postal Bag Filling

The system automatically picks up product and places it directly into each shipping postal bag.

It works by feeding products along a conveyor where they will be scanned. The system can read a barcode, and if required measure the size and weight. The product is then picked up and placed into the correct bag. The automatic XY-A system fills up to fifty four bag locations. This minimises manpower and give you a cost effective solutions for placing products directly into the final destination carrier.

- Product types can be shipping bags, carton sleeves or boxes.

- These are fed into the system on a conveyor. A barcode camera scanner will identify the product and which final postal bag it goes into.

- The XY-A pick head automatically picks up four items in one movements. It then rapidly moves to the location for each product taking an efficient route. When it arrives at the location the vacuum releases the product into the final bag/carton.

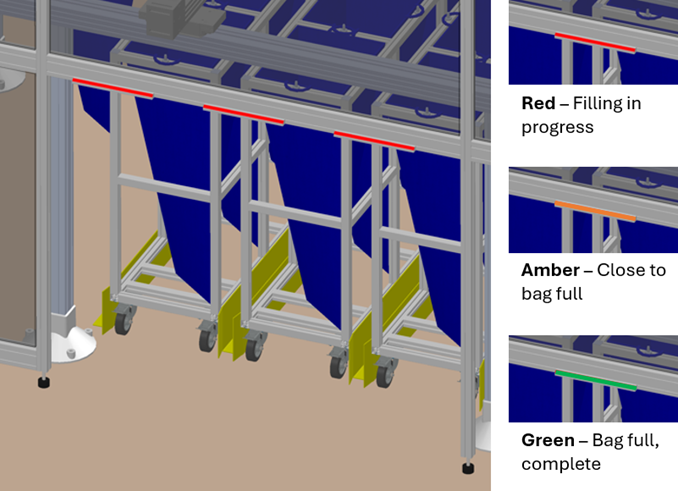

- A lighting system tells the operator when a trolley of bags is full and ready to be removed.

- Software and a HMI touch screen links to the site Warehouse Management System (WMS) or site database.

- Cycle time up to approx. 1500 products per hour handled by one operator, handling one product every 2.5 seconds.

- Up to 54 sort locations in one system.

- Multiple XY-A’s can be linked together.

Trolley Positions – Trolleys are located in the system with floor guides. LED light tells the operator the trolley status. A safety light curtain keeps the operator safe. Trolleys are removed when they are full, and are then be replaced with empty postal bags ready for refilling.

Trolley – Trolley holds three postal bags and is movable on wheels with a handle to hold. Bags can be removed and replaced through the side access of the trolley.

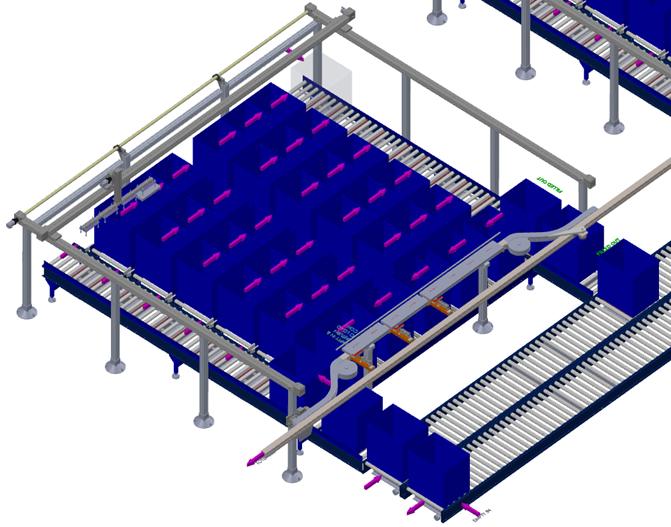

MONK XY-B System – For Tote or Case Filling

This system works with the same XY-A picking system, but has the added feature of feeding totes. Conveyors automatically move the totes into position ready to be filled. When totes are full they automatically leave the system. A number of XY-B systems can be linked together as part of a fully automated conveyor filling system.

Cartons, Cases or Boxes can also be used and the system operates in the same method. A case erector or sealer can be added to complete the whole automation process.