Optical Lab Conveyor System & Stores

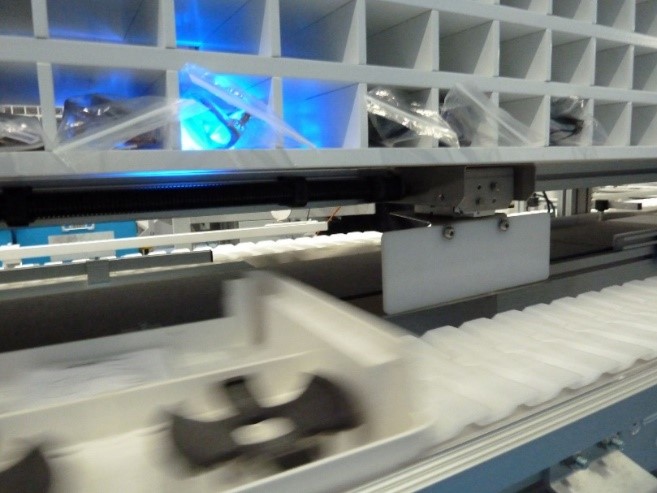

Our optical conveyor systems can help improve efficiency in a stores area, by moving job trays to the pick area and then feeding them onto the next part of the process in the lab.

Manual Picking Options

If racking and manual picking is used, then trays on the optical lab conveyor often need to be stacked. Our conveyors can feed job trays into our automatic Lens Tray Stacking and Tray De-Stacking machines. Trays can be automatically stacked or de-stacked and our optional bar code distribution system can be used to route individual jobs to specific areas of the lab.

- Stacking Machine automatically takes in individual trays and stacks them up in stacks of ten.

- De-Stacking Machine automatically takes in stacks of trays and feeds out individual trays.

- Sensors and software control automatically manages the optical lab conveyor system.

- Automatic conveyor feed to work stations can be provided to fit with the available space.

- A continual flow of work can be maintained to the production area.

Optical Lab Pick to Light System

A Pick to Light System shows staff quickly and efficiently where they should pick from. The system lights up a shelf location or pocket within a stores area. Staff see the light and know instantly this is the location of the optical job they need to pick.

Boxed lenses, frames, or cases can be stored in the system. When they are required the system will then light up the pocket and they can be picked. Conveyors will then feed the job tray to the next part of the process.

Visit our Pick to Light page for more information and videos on our systems.

Robotic Picking Options

If an Automated Robotic Picking System (supplied by RAX) is used then we offer both an infeed and an outfeed conveyor system.

Infeed System is for Boxed Lenses and uses a small compact conveyor to feed individually boxed lenses to the loading area of the store. Our system copes with the large variety of box sizes on the market. We can feed to a number of machines at the same time.

The store then holds a large quantity of lenses in a very compact space using its robotic picking arm.

Around 600 boxed lenses per hour can be automatically fed to the machines. This figure is based on 4 machines and speeds will depend on the size of each machine.

Outfeed System is for Job Trays to be loaded with boxed lenses ready to be processed by the lab. Our optical lab conveyor system feeds trays up to the machine so boxes can be automatically picked and placed in the tray. A number of loading points can be operated at the same time. The tray is then moved away from the machine ready for the next operation.

Around 300 trays per hour can be automatically fed to the machines. This figure is based on 4 machines and speeds will depend on the size of each machine.