News

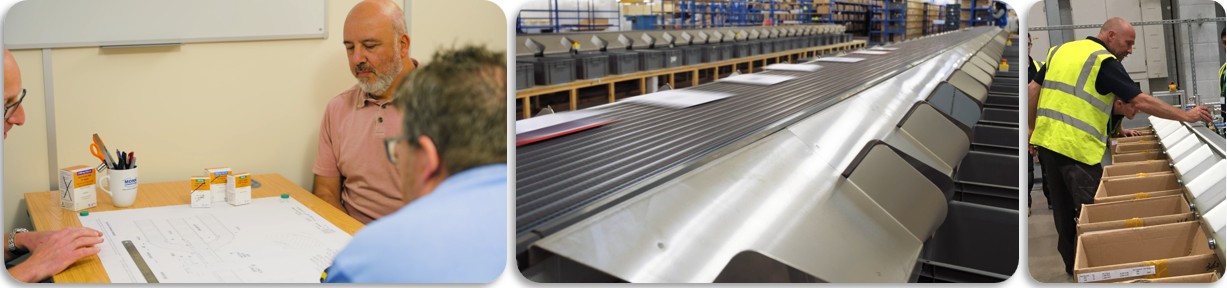

MONK Can Help You Improve Efficiency

Imagine if you invested in automation equipment which saved space, time and reduced your costs. A conveyor can reduce handling […]

> Read MoreEfficiently Move Products Between Floors

Our Spiral Conveyor systems are a highly efficient way to move products up and down from mezzanine floors or over walkways. The […]

> Read MorePallet Handling Roller Conveyor Systems

MONK Conveyors pallet systems provide the in-plant transport links between production, warehouse, order picking and despatch. All too often pallets […]

> Read MorePick to Light Assembly System

The Pick to Light Assembly System allows you to pick and assemble your product in a controlled sequence, and reduces […]

> Read MoreImprove Your Site Productivity in 2025

MONK provide automated conveyor solutions, designed to help optimize factory efficiency, enhance productivity, and reduce your operational costs. We can […]

> Read MoreImprove Your Productivity

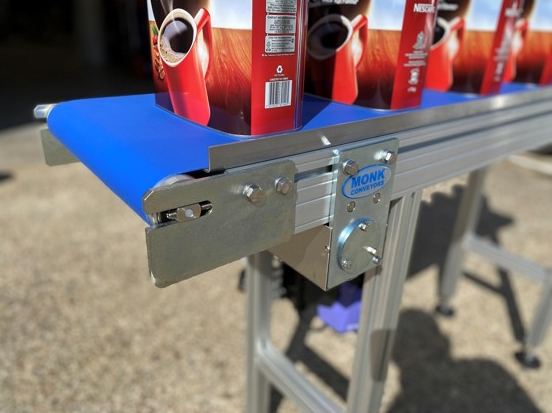

MONK specializes in providing automated conveyor solutions, designed to help optimize factory efficiency, enhance productivity, and reduce your operational costs. […]

> Read MoreCost Effective Conveyor Solutions

MONK supply conveyor systems and product handling solutions to a wide range of industries. We listen to customers and always […]

> Read MoreWarehouse & Logistic Conveyor Systems

Warehouse and Packing The right conveyor system in your warehouse can reduce manpower, improve packing accuracy and increase productivity. We […]

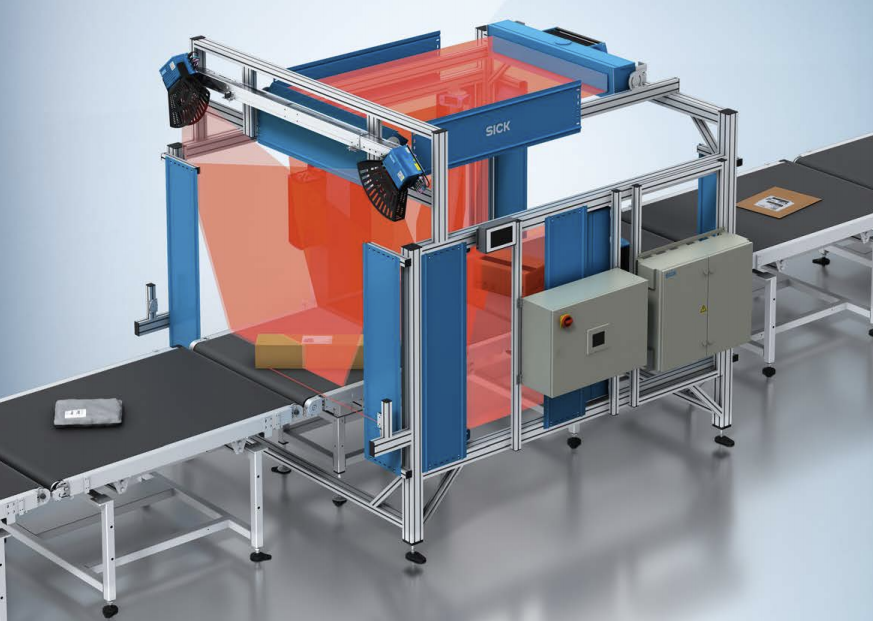

> Read MoreMeasure, Weigh & Identify Parcels

MONK’s installation partnership with SICK means we can provide class leading weighing, measuring and product identification conveyors at speeds of […]

> Read More