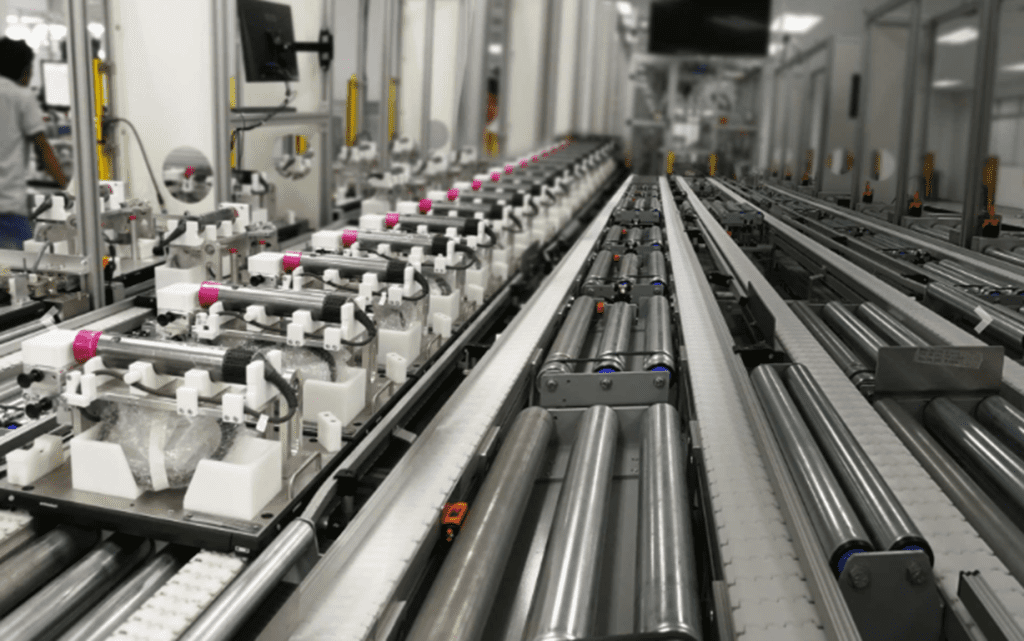

Battery Conveyors

Battery conveyors are essential for safe handling and manufacturing by automating the movement of batteries and their components between different workstations and processes.

Our flexible chain and belt conveyors will provide the optimised movement of parts, as our systems are designed to handle batteries with care. Plus, the risk of damage is reduced by reducing manual handling during the assembly process. Battery conveyors also reduce the need for workers to manually lift and carry heavy batteries, minimising the risk of workplace injuries.

MONK Conveyor systems can be customised and scaled to accommodate different battery production volumes and layouts, making them adaptable and flexible for future manufacturing needs.

Our battery conveyors and software can be integrated with other automated systems like robotic pick-and-place equipment, vision systems for quality control, and automated guided vehicles (AGVs) for material delivery, creating a highly automated and efficient battery production line.

Monk’s conveyor control software and touch screens make systems easy for operators to use and configure. Our barcode, camera systems and RFID readers mean we can identify battery components to sort them or route them around your site. Our KPI reporting system can provide useful data to measure the performance of your conveyor system or operators.

Our range of roller conveyors, belt conveyors, pallet conveyors, spiral conveyors, in-house control panel building and software means we can offer you a complete turn-key solution which is tailored to your specific needs, while being reliable and robust battery conveyor systems which are easy to look after and maintain.

“Monk helps you handle batteries and components in a safe and efficient manner”