Roller Conveyors

Monk’s roller conveyors are a cost effective way to move your products and automate. Using roller conveyors can optimise your workflow by keeping product moving, increasing throughput whilst reducing manual handling. This can also free up staff for more complex tasks and improve safety when moving bulky or heavy items.

Request a QuoteRoller Conveyor Systems

Roller conveyors can be integrated with other existing automated systems to further increase efficiency, like automatically feeding to packing lines, case sealers and robot palletisers. Our roller conveyors systems are versatile, customisable and can be designed to fit your space, plus they can handle a large variety of products.

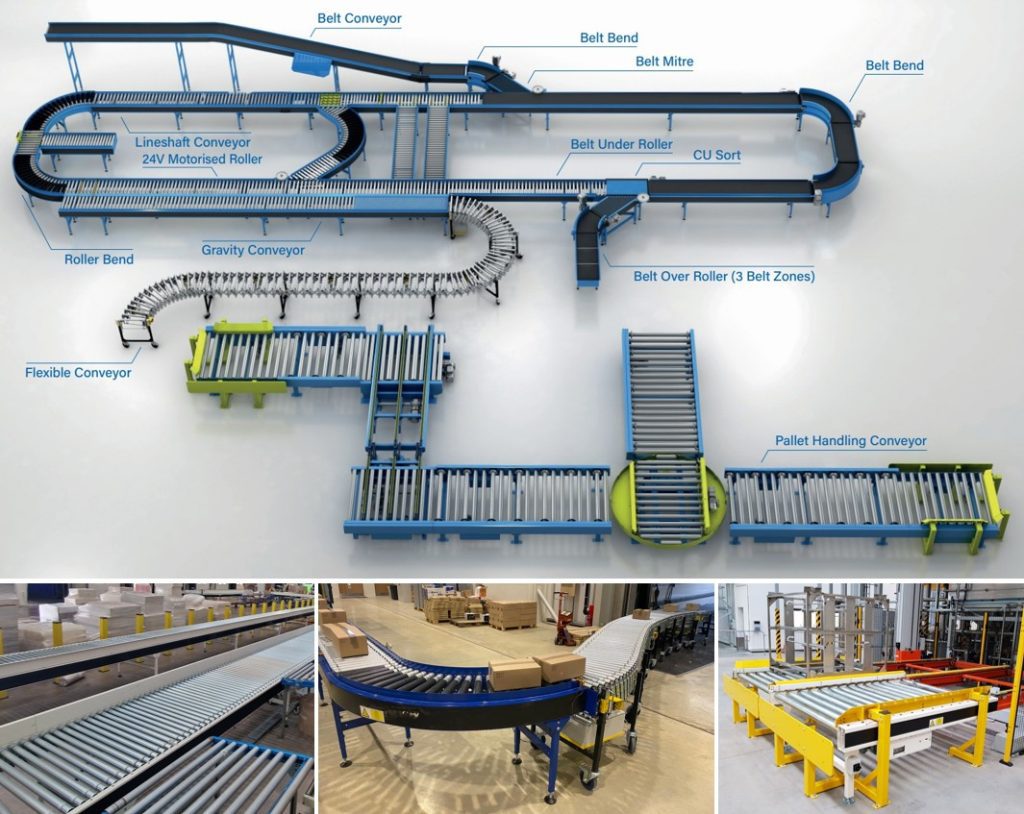

Types of Roller Conveyor

Roller conveyors are available in gravity or powered sections which can be suitable for straight long runs or complex configurations. Powered Line shaft Roller Conveyors run with fewer drives compared to conventional powered equipment. Product can also be driven in small zones, so it is easy for operators to remove and place items on the conveyor line. Our roller conveyors are modular and can easily be reconfigured to meet future demands. Full system design, mechanical and electrical installation can be provided along with software and easy to use operator touch screens.

Request a QuoteHow Roller Conveyors are Used

Typical products for roller conveyors would be cartons, tote bins and packed items, all which will need to have a flat base. Pallets will also run on our roller pallet conveyors.

Key Features:

- Robust powder coated steel beams

- Proven product, highly configurable, reduced installation time.

- Quiet running providing a good working environment.

- Numerous ancillary modules – Blade Stops, Side Transfers, Switch Sorters, Merges etc.

- Powered Lineshaft, 24V DC Sections, Belt under roller, Gravity and Chain systems for pallets are available.

- Modular design means that sections are easily added or removed to meet current and future demands

- Safe operation

- Low maintenance design.

- 1-Year mechanical warranty

- CE Marked

For more information about roller conveyors, download the PDF catalogue or send us a message.

Lineshaft Roller Conveyors

The most versatile and economical powered roller conveyor available. Ideal for straight long runs or complex configurations. Fewer drives are required compared to conventional roller conveyor systems. Another unique advantage of Lineshaft Roller Conveyors is the number of ancillary modules which can be driven from one motor by means of couplings and universal joints. Available in powder-coated steel as standard also available in aluminium.

- Roller sizes: 25.4, 35 & 50mm diameter.

- Standard conveyor widths available: 412, 462, 512, 612, 762 and 912mm.

- Drive up to 36 metres from one 0.37Kw drive unit.

- Supplied in 3 metre fully assembled lengths as standard.

Below are a few examples of handling modules available.

Chain and Belt Transfer Unit

Allows products to be lifted and transferred sideways off of the conveyor to a different route. The product stops and the transfer belts lift up between the rollers to drive the product sideways.

- Available in twin or triple chain transfers using steel or nylon chain

- Maximum lift twin chain 50Kgs.

- Maximum lift triple chain 100Kgs.

- Maximum of 15 operations per minute.

- Drive to the transfer chains is via sprockets on the main lineshaft.

- The rise and fall of chains is actuated by double acting cylinder(s).

- Standard conveyor widths available: 412mm, 462mm, 512mm, 612mm, 762mm and 912mm. Other widths available on request.

Switch Sorter

Allows products to be transferred off the conveyor to a different route while continuously moving. The switch sorter roller quickly turn by 45 degrees to send the product down a different route. The product can continuously move, so this is ideal for higher throughput. Units can also switch to the left and the right, which gives up to three possible routes.

- Incorporates double acting pneumatic cylinders.

- Can be supplied right handed, left handed or bidirectional.

- Minimum product size 200mm x 200mm.

- Available with 45 switching angle.

- Normally used in conjunction with a 45 degree mitre section, although other options are available.

- Standard conveyor widths available: 462mm, 612mm, 762mm and 912mm.

Vertical Blade Stop

Allows products to be stopped and a queue can be created. A safe device for operators and robust for use with light and heavy products.

- This stop can be incorporated into straight roller conveyor track.

- Speed up spools are supplied at the stop position to increase gaps between loads.

- Incorporates double acting pneumatic air cylinder.

- Standard conveyor widths available: 412mm, 462mm, 512mm, 612mm, 762mm and 912mm. Other widths available on request.

30° Merge Unit

Allows products to merge into the main conveyor line.

- Right and left hand merges available.

- Has the ability to merge tracks at 90 and parallel lines when using 60 and 30 bends.

- Merge unit includes jump chains and universal joints which allow the drive to be continued through the unit.

- Supplied with a turning wheel for positioning at the leg intersection to assist with guidance of the product.

- Maximum throughput of 25 packs per minute based on conveyor speed of 50 metres per minute.

- Standard conveyor widths available: 412mm, 462mm, 512mm, 612mm and 762mm. Other widths available on request.

Lift Gate

Allows staff to enter areas for maintenance or emergency access. The lifting action is assisted by two gas struts to help staff raise the gate. They also give a smooth dampened stop when the gate goes to its open and closed position.

- 900mm clear access given when gate is in the ‘up’ position.

- To be used for emergency access only.

- Can be positioned back to back to give a ‘TowerBridge’ arrangement.

- Standard widths available: 412mm, 462mm, 512mm, 612mm, 762mm and 912mm. Other widths available on request.

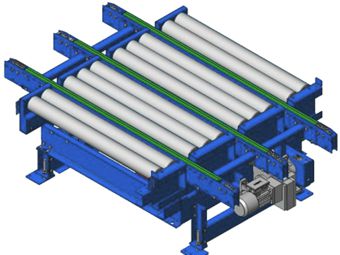

Pallet Handling Roller Conveyors

Designed for flexibility and heavy duty usage – up to 4500kg per pallet. The modular pallet conveyor range comprises a heavy duty chain conveyor, roller conveyor, chain transfer and turntable modules. The flexible pallet handling roller conveyor system is designed to handle the full range of Euro-pallet sizes as well as the popular Cheap type 1200 x 1000mm pallet, with loads up to 1500kg.

- Roller conveyors tangentially driven by 5/8” chain in a fully enclosed side channel.

- Load capacity of 1500kg per pallet.

- 3mm and 5mm thick roller options.

- 150mm or 200mm roller pitch.

- Ability to run cables in a channel with fascia to close section off.

- Standard conveyor lengths available – 1050mm to 6000mm in 150mm increments and 1200mm to 6000mm in 200mm increments.

- Speeds available 12 to 18 metres per minute.

- Pallet size – 800mm wide x 1200mm long (1000Kg) / 1000mm wide x 1200mm long (1500Kg).

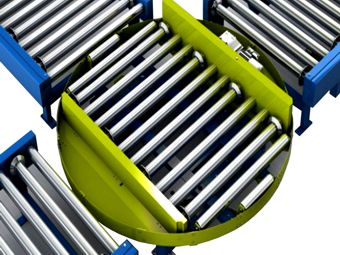

Roller Conveyor Turntable

- Changes the direction of pallet travel by rotation of the pallet through any angle from 90 up to 180, whilst keeping the relationship of the pallet runners to roller conveyor the same

- Range of heights available from 400mm – 1150mm top of roller

- Motors available – roller conveyor 0.37 kW (12 metres per minute), roller conveyor 0.55 kW (18 metres per minute)

- Pallet size – 800 / 1000mm leading edge on rollers x 1200mm long

- Two rotation speeds available – rotation drive 0.18kW (2rpm), rotation drive 0.37kW (4rpm)

- Up to 174 pallets per hour rotating 90

- Roller and turning motors supplied braked as standard

Single Chain Transfer

Allows pallets to be lifted and transferred sideways off of the conveyor to a different route. The pallet stops and the transfer chains lift up between the rollers to drive the product sideways.

- Nominal roller pitch of 150mm for all pallet types, offering exceptional support for pallets during the transfer operation

- Load capacity of 1500kg per pallet

- Electric lift action

- Bidirectional chain and rollers as standard

- Range of heights available from 425mm 1000mm top of roller

- Speeds available – 12 and 18 metres per minute

- Up to 213 pallet transfers per hour

Bash Plates and End Loading Side Guards

- Heights – available from 400mm – 1150mm top of roller.

- Widths – 1600mm or 1800mm.

- Function – protects conveyor from FLT damage.

- Floor mounted ensures no forces transmitted into roller conveyor.

End Loading Side Guards

- Heights – available from 400mm – – 1150mm top of roller.

- Widths – 1135mm or 1400mm.

- Function ensures correct pallet positioning and protects roller conveyor from damage.

- Floor mounted ensures no forces transmitted into conveyor.

Gravity Roller Conveyors

The most cost-effective conveying solution. Gravity roller conveyors are the most economical and simplest way of transporting loads from one point to another. Minimal effort required in the movement of goods whether it is manual assistance or gravitational force.

- Available in light or medium duty versions.

- Standard roller conveyor widths available: 312 -1012mm (in 50mm increments).

- Static load per roller – up to

- Can be supplied with locking casters.

- 50mm or 60mm dia. rollers can be fitted from 75mm to 150mm pitch.

- Rollers are zinc plated as standard.

- Available powder coated and aluminium.

Gravity Roller Table

- Plastic free running rollers

- Close pitch for small products

- Low friction

- Steel or aluminium tracks

Zero Line Pressure

This conveyor technique uses 24VDC motors to drive individual short conveyor sections. It can be used to keep work apart by moving it in small powered zones. There is no back pressure and operators can easily remove any product from the conveyor. The queue of work then automatically moves forwards to keep the conveyor line full.

- Offers extreme versatility in the transportation of various totes / cartons, whilst providing ultra-efficient accumulation.

- Available in steel powder coated as standard

Flexible Roller Conveyors

Powered Flexible Roller Conveyor

The perfect roller conveyor for vehicle loading and unloading, parcel distribution centres and depot’s, packaging, machine-to machine-linking and all cross docking applications. Very easy to quickly move in or out of trucks for faster, safer, easier loading and unloading.

- Roller conveyor speed is fully adjustable from 10 to 40 metres per minute; 0.09Kw for 230/240V single phase supply.

- Side plates manufactured from high quality, bright zinc plated steel plate with ribbed design to ensure maximum strength and durability.

- Fully bolted design not riveted.

- Support legs are fully adjustable from 770mm to 1095mm as standard.

- 150Kg load capacity per linear metre based on a level working height.

- 600mm and 750mm standard conveyor widths (900mm width option).

- All support legs have welded braces for additional strength and rigidity.

- Heavy duty castors – 160mm x 50mm swivel castors for maximum manoeuvrability. The castor wheel incorporates a foot operated brake.

Gravity Flexible Roller Conveyor

Very easy to quickly manoeuvre in or out of trucks for faster, safer, easier loading and unloading.

- Standard conveyor widths of 450mm, 600mm 750mm or 900mm

- Support legs are fully adjustable from 750mm to 1035mm. Other heights available upon request

- 250Kg load capacity per linear metre based on a level working height

- All support legs have welded braces for additional strength and rigidity

- Heavy duty castors 125mm x 36mm swivel castors for maximum manoeuvrability. The castor wheel incorporates a foot operated brake

- Roller centres 125mm as standard when the conveyor is fully extended. Optional 75mm and 100mm roller centres can be supplied for the conveying of smaller packages or cartons

Gravity Flexible Skatewheel Conveyor

A rugged conveyor ideally suited for many roles from packaging and flexible assembly lines to loading and unloading of trucks and containers. The conveyor is easy to move around on heavy duty castors and simply compacts to a quarter of its size when not in use.

- Support legs are fully adjustable from 750mm to 1040mm as standard

- 300Kg’s load capacity per linear metre based on a level working height

- Standard conveyor widths of 450mm, 600mm, 750mm and 900mm

- All support legs have welded braces for additional strength and rigidity

- Heavy duty castors – 125mm x 36mm swivel castors for maximum manoeuvrability. The castor wheel incorporates a foot operated brake

- Roller centres 125mm as standard when the conveyor is fully extended. Optional 75mm and 100mm roller centres can be supplied for the conveying of smaller packages or cartons. Please note optional roller centres will affect the conveyor compacted length

© Monk Conveyors 2026Company Registered Number: 4014039