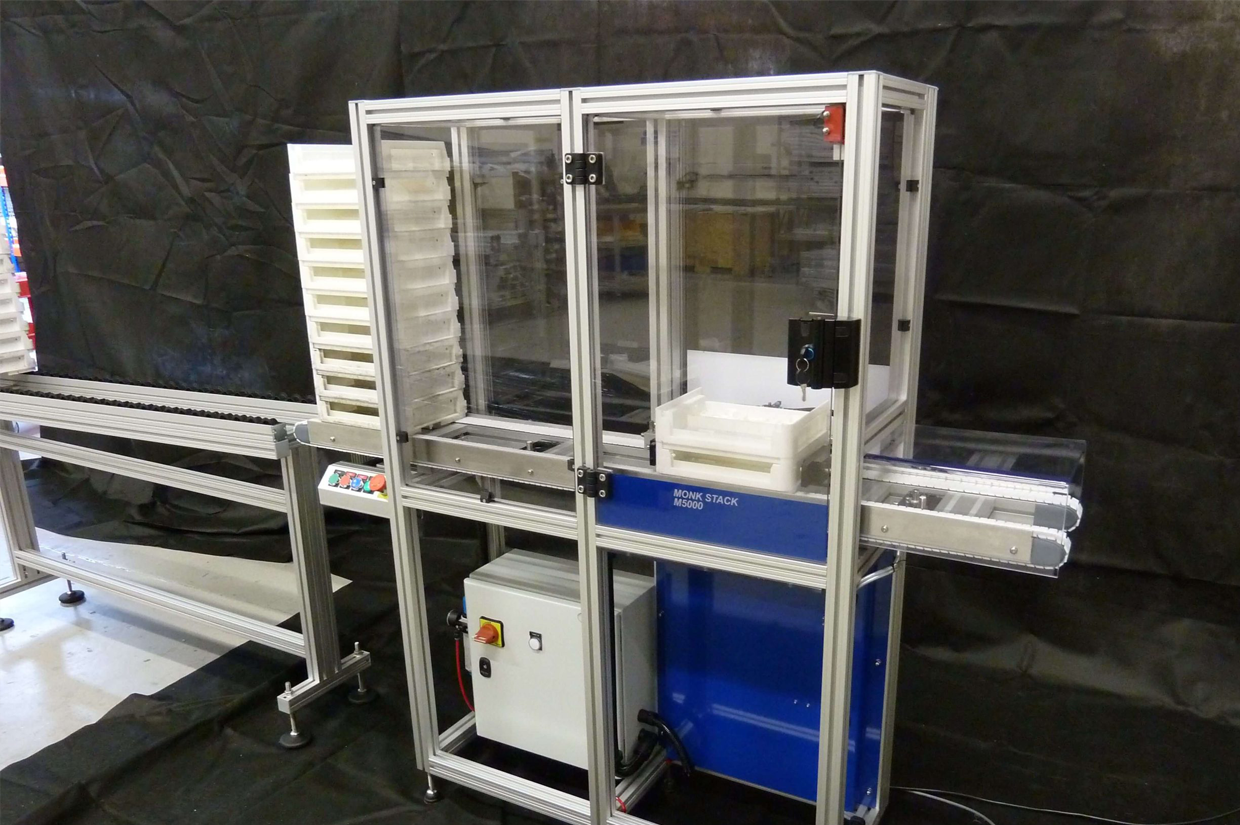

Auto Stacking Machine

Auto Stacking Machines can offer big advantages in some manufacturing or warehouse packing facilities by automatically stacking trays, plastic totes, pallets or products.

An Auto Stacking Machine allows a queue of product to be fed into it on a conveyor. It will then take one item at a time and stack it onto the next. Once the stack is complete, it is automatically released onto an outfeed conveyor and the auto stacking machine starts creating a new stack. The reverse operation can also be carried out to automatically De-Stack. This means taking a stack and releasing one item at a time from the stack onto an outfeed conveyor.

Advantages of using an Auto Stacking Machine to stack and de-stack product:

- Stacked work saves floor space

- Products which require time to cure or cool can be stored in a reduced floor space

- Work can be stacked to create a buffer between machines or processes

- Stacked products can be easier to pick up and pack into boxes

- No operators are required as the machine will automatically create a stack

- The number of items in a stack is counted and controlled

- End of line product stackers can help a reduced number of staff look after a number of different lines

Automatic Stackers

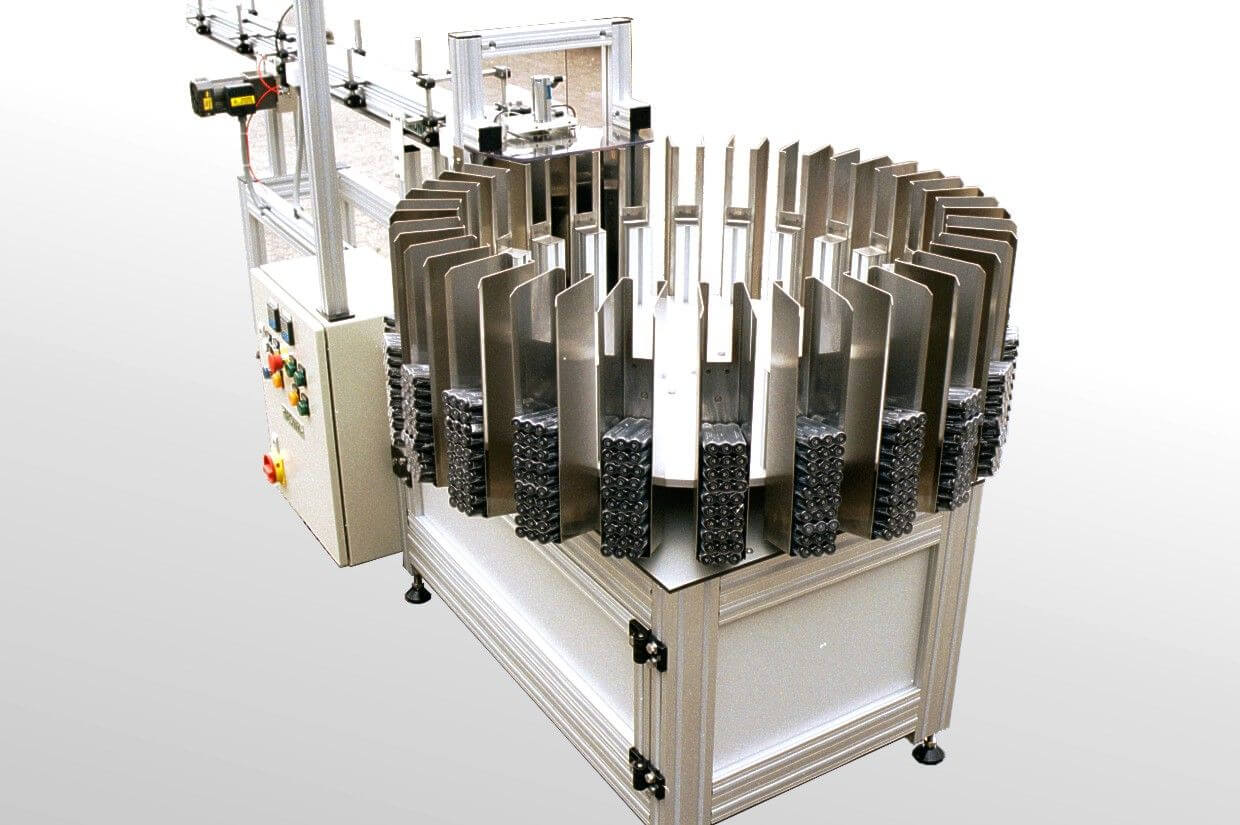

Automatic Stackers use as many of our standard modules as possible and are kept simple and easy to maintain. Designs are adjusted to suit the specific product and application. Machines normally include pneumatics cylinders, with electrical movement also being an option. The control system includes PLC, software, safety circuits and guarding. Infeed and outfeed conveyors help to achieve a fully automatic stacking system.

Please contact our sales team who will be happy to discuss your application.

Tote Stacking for Hewlett Packard

Stacked Totes Loaded onto Pallets

Optical Tray Stacker and De-Stacker

End of Line Product Stacker for Cosmetics

Product Tray Stacking for Epson